Applicable Industries:

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Building Material Rolling Shutter Metal Door Frame

Showroom Location:

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam

Condition:

New

Type:

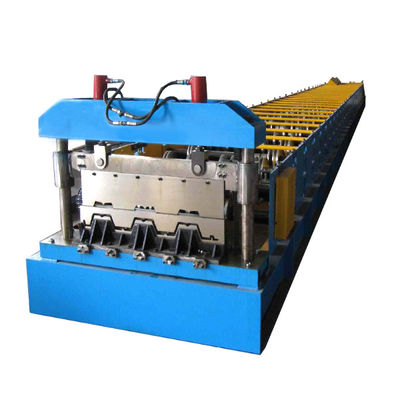

Tile Forming Machine

Tile Type:

colored

Use:

ROOF

Production Capacity:

15 m/min

Voltage:

380V

Dimension(L*W*H):

4.5-5.5m

Weight:

3 kg

Warranty:

1 Year

Key Selling Points:

Easy to Operate

Rolling thinckness:

0.3-1mm

Feeding width:

1220mm

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Marketing Type:

New Product 2020

Warranty of core components:

1 Year

Core Components:

Pressure vessel, Motor, Bearing, Gear, Pump, Gearbox, Engine, PLC, Building Material Rolling Shutter Metal Door Frame

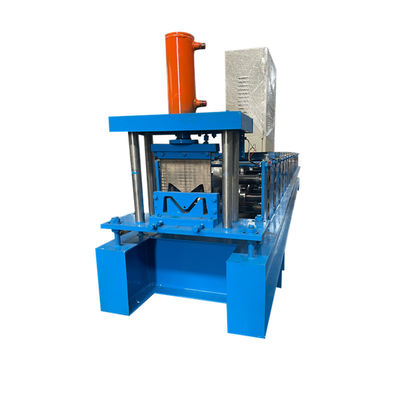

Name:

Floor Deck Roll Forming Machine

Raw material:

Galvanized Sheet

Shaft material:

High Grade No.45 Forged

Control system:

PLC(imported Brand)

Material:

Color Steel Galvanized Plate

Thickness:

1.5-3mm

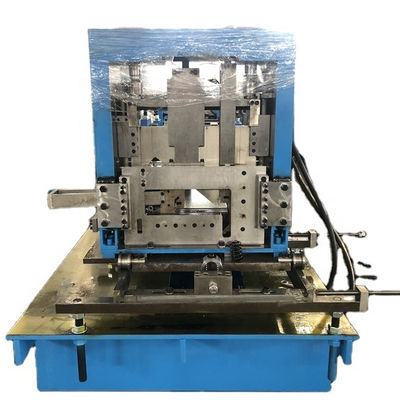

Cutting type:

Hydralic Cutting

Roller stations:

18 Stations Roll Forming Machine

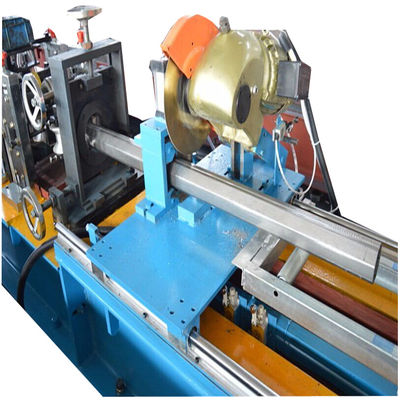

Decoiler:

Hydraulic Decoiler

Profiles:

Metal Roof Forming Machine

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!